The Fiber Optic Technology Future

(blogger@L-com.com)The emerging field of fiber optics is no longer emerging; it's here. That's because manufacturers get better at making fiber cables and lasers each year, all amidst some of the highest prices for copper we've seen. Already, dead-run fiber networks are cheaper and greener than twisted pair cabling. Fiber is here. Are you ready?

The New Rules of Fiber

If you are not used to working with fiber, you may assume it has similar factors as an Ethernet UTP or STP cable: run it at 90 degree angles from power cables in the wall, and terminate it with a jack at each workstation or drop point. However, fiber optics are very different from copper cables (if you are interested in all the differences, there's a great tutorial on fiber optics here), and so the old rules no longer apply. Instead, you have a whole new set of problems that you need to look out for. Here are a few of the most common.

Cleanliness is King

In a copper world, dirt and dust can erode a connection over time. Therefore, in an industrial setting where a lot of dust might be present, IP67 rated and harsh-environment Ethernet cables are best to extend the life of your network. In fiber, however, dirt and dust don't just erode a connection, they kill it altogether. Dust particles that are far too tiny to see, residue from cleaning products, and even the oil from a fingerprint can outright stop a fiber signal from connecting. Therefore, a technician working on a fiber network needs fiber optic cleaning supplies. Some examples of what you'll require are:

|

|

Hellermann/Tyton's Fiberclean- Fiber Optic Connector Cleaning System |

Senko's Fiber Optic Cleaner for SC, FC and ST simplex connectors |

|

Senko's Fiber Optic Cleaner for LC and MU simplex connectors |

In addition, you may want to stock up on some general fiber optic cleaning materials:

Matching the Cores

In twisted pair cables, there are different sizes and styles. You can have a cable backbone using 22 AWG copper, and then patch cords using thinner 26 AWG copper. Chances are the backbone used solid conductors, while the patch cords use stranded. You may also have a shielded cable somewhere in the mix, which you know has to be grounded at both ends. But aside from the grounding, all of these different components easily connect together.

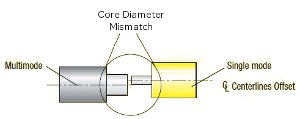

Not so with fiber optics. Your 62.5/125 fiber will not work properly if you connect it to a single mode switch. And if you use a 50/125 fiber cable, you'll find it isn't backwards compatible with a network composed of the larger 62.5/125. If these terms are confusing you, see a helpful video here that explains it better.

Fortunately, most fiber optic cable manufacturers will not only stock cables in all three of the most common diameters, they will also offer custom fiber optic manufacturing services, where they will build exactly what you need at exactly the right length. L-com, for instance, offers this service without any minimum order quantities, and with ultra-short lead times because of their domestic manufacturing capabilities.

Polishing the Connectors

Another factor to consider with fiber cabling is the polish used on the connectors. This is one of the new considerations that makes terminating a fiber cable in the field so difficult. Because light can be reflected back at the connection point, a special polish is needed, and that is much easier to do in a factory.

There are three polish types that are common: PC, ultra PC (or UPC), and angled PC (or APC). While PC is the general standard, you should always check to see if your active equipment calls for the more stringent UPC polish type. Applications requiring APC are not common, but when you need APC there are even more factors to consider… Since because of the angle in APC, the two connectors at a connection point must line up, which is nearly impossible for round connectors like the ST and FC types. There are "keyed" versions of FC connectors that can allow this, but most of the time you would need a rectangular connector like an SC or LC. Also, fiber optic attenuators and adapters must be specially made for APC applications.

Getting Fiber Optic Help

Don't be ashamed to seek help if you are dealing with fiber optic products for the first time. There are many pit-holes like the above. Consider hiring a professional fiber optic contractor, and call the tech support professionals offered by your cable manufacturer with your questions. Learning about these problems ahead of time can save you a lot of headaches later.

No comments:

Post a Comment